Advance PWBs Gain Traction in New Growth Fields

In heat-dissipation FPCs, the use of light-emitting diode (LED) lamps in automotive has become widespread already. Typical heat-dissipation FPCs include metal-based FPCs that combine aluminum and copper with FPCs, and heat-diffusing FPCs that dramatically improve heat dissipation effect through the bonding of ultrathin polyimide film on the metal case.

There are also a wide variety of technologies for robots. Three-dimensional (3D) forming FPCs achieve repeated stretching by means of stereo molding through the adoption of liquid crystal polymer with excellent moldability. These can also be formed into 3D embedded shapes.

The adoption of FPCs for automotive application has been expanding with infotainment, switches, sensors, lights, and powertrains as main applications.

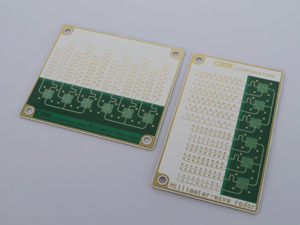

Photo 2: Hybrid PWBs for millimeter wave radars that combine the

antenna section and the control section in a PWB (CMK Corporation)

ADAS Gathers Steam

In the automotive field, manufacturers provide optimally designed, application-specific PWBs particularly for powertrain system, vehicle control system, body system, and information and communication system. Recently, circuit boards for millimeter wave radar units and camera modules for ADAS are attracting attention.

A millimeter wave radar unit comprises of a high-frequency section of an antenna and a control circuit equipped with semiconductor chips. A conventional millimeter wave radar unit required two PWBs.

Recently, PWB manufacturers have developed technologies to replace two PWBs using a single high-frequency hybrid composite multilayer PWB from the viewpoints of downsizing units and reducing costs. Leading manufacturers have already been making concrete capital investments in preparation for mass production.

On-board cameras, which are important components for ADAS, require scaled down module PWBs in order for them to fit in small and complex locations. Rigid PWBs adopt the build-up method in order to accommodate thickness reduction.

English

English Japanese

Japanese