Panasonic Makes Available Smart Manufacturing Software Solution

JAPAN – Panasonic Corporation has introduced its Manufacturing Operations Optimizer (MFO) software solution, a system that improves productivity by utilizing a simulation model that accurately emulates the mounting process of electronic components on printed circuit boards.

Creating an optimal manufacturing execution plan requires excessive man-hours and expert's know-how, which resulted in a gap between production plan and actual production, and decrease of productivity. To solve these problems, Panasonic integrated a Siemens production process simulator "Plant Simulation" module and Panasonic's proprietary know-how on mounting process to develop the new system.

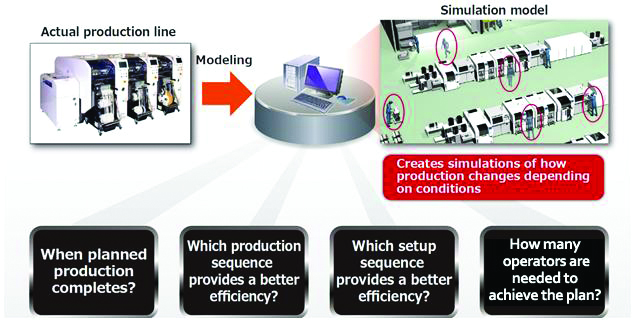

Framework of Panasonic's Manufacturing Operations Optimizer (MFO) software solution

This system dynamically analyzes changes in production details according to the site conditions by simulating the entire mounting process including equipment of other companies and workers, and based on the results, automatically determines the optimal execution plan to connect the production plan and actual production.

www.panasonic.net

English

English Japanese

Japanese